Machine for OCD-4-ring-mechanisms:

Maintenance measures und new control station

Our machine for OCD-4-ring-mechanism on base width 27 mm undergoes a 4-week general overhaul this spring.

What happens exactly?

- All wear parts will be exchanged:

e.g. chain guides, gear wheels, valves, sensors, wires, air tubes, electronic contacts - Set-ups for occupational safety will be renewed:

e.g. safety switches and perspex

The aim of these extensive measures is to ensure machine capacity and product quality long-term.

Additionally, there will be installed a new control station for quality assurance.

It scans every single ring binder mechanism during the production process, to check the ring strips’ exact positioning in the base plate.

This facilitates height difference checks with the exactness of a tenth of a millimeter and increases the process and quality assurance many times over.

Machine for types SXR 272/04/16 and 20(15):

Innovative camera station

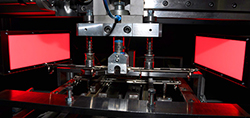

At the machine for the types SXR 272/04/16 und 20(15), there has recently been installed a camera system for quality assurance. The camera, which works in the dark by using red light, registers differences in side and height offsets smaller than 0.1 millimeter.

At the machine for the types SXR 272/04/16 und 20(15), there has recently been installed a camera system for quality assurance. The camera, which works in the dark by using red light, registers differences in side and height offsets smaller than 0.1 millimeter.

During the manufacturing process, a 100% product check is done. Mechanisms which show a difference in side or height offsets are automatically ejected. Thus it is provided, that only flawless goods are delivered to our customers.

(March 2014)